When cracks were found on the bodyshell (yaw damper bracket and anti-roll bar fixing points) of some trains, rigorous safety checks by Hitachi Rail and the train operators impacted were carried out, with oversight from ORR.

Stringent mitigation measures were put in place to allow the trains to re-enter service without passenger safety being compromised, which have assured no safety failures and trains have performed as specified while in service.

ORR immediately launched a review of both the passenger and safety impact after trains were withdrawn from service for safety checks on Great Western Railway, London North Eastern Railway, TransPennine Express and Hull Trains, along with cracks being separately discovered after examination on ScotRail’s Class 385 and Southeastern’s Class 395 trains.

Rail engineers from the manufacturer, Hitachi Rail, and independent experts have also completed rigorous analysis to gain a clearer understanding of the issue.

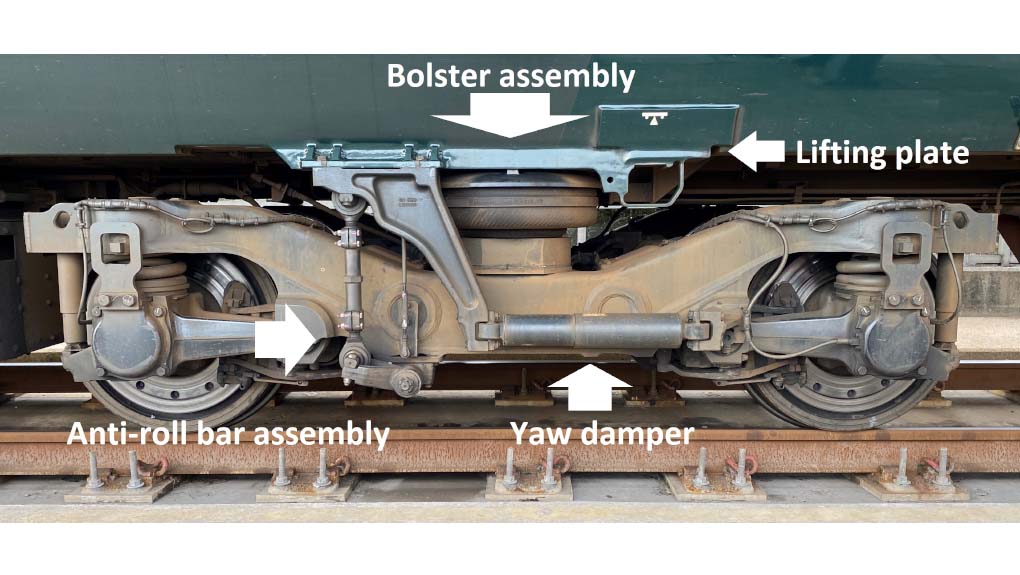

ORR’s review concluded that on the vehicle body in the area above the wheels close to the yaw damper bracket and anti-roll bar fixing points, fatigue cracking was caused by the trains experiencing greater loads from train movement than allowed for in the original design. It is not yet known for certain why this happened, although potential factors include wheel wear and track design.

Additional cracks found in the area where the lifting plates attach to the vehicle body were the result of stress corrosion cracking (SCC), resulting from the use of the particular type of 7000 series aluminium in various areas of the Hitachi Rail Class 800 series.

The characteristics of the specific aluminium alloy in combination with built-in stresses from being welded to the body and exposure to air containing chloride resulted in cracking.

To ensure further safety improvements, ORR is recommending that:

- The industry should conduct further work to identify the reasons for the higher levels of fatigue loading experienced by rolling stock. Since the Hitachi Rail design complied with the applicable industry standards, the industry as a whole should evaluate whether the applicable standards take into account the loads arising from operation on the rail network in Great Britain. This industry collaboration will require the involvement of those parties responsible for design, manufacture and maintenance of rolling stock including, but not limited to, Hitachi Rail.

- Hitachi Rail should carry out a formal review of the effectiveness of their processes for welding when the component geometry is more challenging, which should include consideration of whether the existing approach adequately mitigates the risks of a weld with insufficient fusion being accepted.

- Designers of rolling stock should understand the risk posed by stress corrosion cracking and give it specific consideration when proposing the use of 7000 series aluminium components. This does not mean that the specific type of aluminium should not be used in future, or that the aluminium used in the current trains compromises safety; but when used, steps should be taken to ensure protection of structures.

- The industry should consider whether a standard for mitigating SCC risk should be developed, as no dedicated standard currently exists.

- The industry should develop a process for responding to similar future cross-industry crisis events and appoint a strong, independent chair who can maintain pace, focus and ensure all voices are heard.

In addition to conducting its review, ORR has continued to carry out oversight to ensure robust processes are being followed.

Hitachi Rail and its industry partners are about to start the major programme of work to repair 1,247 Class 800 series carriages and a further 487 Class 385 and 395 carriages.

ORR is working with Hitachi Rail and its partners to agree the permanent solution to address the issues. Hitachi Rail plans to replace the affected part of the original body structure, including the longitudinal welds where the fatigue cracks have occurred, and the mounting brackets. Hitachi Rail has also proposed to modify the addition of bolts to retain the plate in the unlikely event that the welds fail completely as a result of the stress corrosion cracking.

It is proposed that this programme is expected to take place over the next six years in order to minimise disruption to passengers while ensuring safety, with the minimum number of units out of service at any one time.

ORR’s review states that Hitachi Rail is prioritising the trains for repair on the basis of need, drawing on the monitoring data it has compiled from the fleet engineering and safety checks.

ORR will continue its oversight and follow the industry’s actions as well as promote the lessons learned in operators’ safety management systems to continue to deliver improvements. The industry has established processes for improving standards and ORR expects that these will be followed promptly.

The regulator praised the rapid industry response and subsequent work to safely reintroduce trains to service.

ORR’s HM Chief Inspector of Railways Ian Prosser CBE said:

Notes to Editor

- The Office of Rail and Road is the economic and safety regulator of Britain’s railway.

- On 8 May 2021, Hitachi Rail’s Class 800, 801 and 802 trains (referred to collectively as Class 80X) operated by London North Eastern Railway (LNER), Great Western Railway (GWR), TransPennine Express (TPE) and Hull Trains were withdrawn from service as a safety precaution after cracks were identified in some carriages of the trains, specifically those in service with GWR and LNER, but not TPE or Hull Trains. The disruption caused by the events on 8 May had an impact on passengers travelling or expecting to do so using the services of these train operators.

- Subsequent cracks were also found on Class 385 operated by ScotRail and Class 395 operated by Southeastern but were not withdrawn from service on 8 May 2021, as their designs are different to the Class 80X and the actual and potential incidences of cracking were assessed as low risk.

- On 7 June 2021, the Office of Rail and Road (ORR) informed Ministers at the Department for Transport of our plan to complete a lessons learnt review into the safety and passenger impact of the issues. We published the ‘Passenger Impact review – Hitachi Rail Class 800 trains’ on 25 June 2021, and an interim safety report on 9 September 2021 addressing the initial findings of the lessons learnt review. This final report covers the safety elements of this review and findings to date.

- Hitachi Rail’s proposed permanent solution to address the fatigue cracking issues in the bolster area is to remove the affected part of the original body structure, including the longitudinal welds where the fatigue cracks have occurred and the mounting brackets. The structure is rebuilt using a modified design (an example is shown in the attached image 1) that provides an unchanged interface with the yaw damper bracket and anti-roll bar. The modifications address the load capability of the design and the potential for insufficient fusion in the welded joint arising from weld design and inspection criteria.

- Fatigue cracking at the yaw damper explained: Fatigue is a mechanism whereby cracks develop and grow (propagate) through a material that is subject to cyclic loading, namely the repeated imposition and removal of mechanical stress. This occurs where the load changes in size, alternately opening and closing cracks at a microscopic level, such as the loads imparted by an anti-roll bar as a train moves from a curve to straight track and back onto a curve. For fatigue to occur the loads must be above a threshold level but are typically much lower than the load required to cause an immediate structural failure of the material. This means that the affected component is initially able to function without breaking, but over time cracks grow and reduce the strength of the component until the remaining uncracked material is not strong enough to take the loads being imparted.

- Stress corrosion cracking in the jacking plate explained: Stress corrosion cracking (SCC) is a mechanism whereby cracks develop in susceptible materials when they are exposed to a specific corrosive environment while subject to mechanical stress. The particular type of aluminium alloy used in the affected parts of the trains is sensitive to the presence of chloride. Moist air can have significant levels of chloride in it picked up from various factors such as from salt used for clearing ice. The affected parts of the trains are under stress because of the way they were welded together. This is not unusual. The stresses involved in SCC are usually significantly lower than those involved in mechanisms where the stress alone is sufficient to cause cracking, thus making certain materials susceptible to cracking under conditions where the mechanical design would otherwise be sufficient to prevent it. SCC has been likened to the fire triangle where fuel, heat and oxygen must all be present for combustion to take place; if any of the three elements are missing then there is no fire. For SCC the three elements are susceptible material, specific environment, and stress.